Tony Vickio-Lap 13

Experiences of "The World Famous"

by: Tony Vickio

Painting at the Famous Race Tracks

Lap 13: Back to the Glen and then back to Talledaga!

The next morning we woke up around 7:00am. That was a good move to get some sleep! Walking out of the motel it was very humid. Looking up at the sky, it looked like we may run into some rain. "Let it rain", I thought. We hit perfect weather the last week, allowing us to get our work done, so I actually didn't mind it raining. We jump in the Mustang, I take the first "tour of duty" driving, turn the key and the engine comes to life. I think, "The poor engine doesn't realize it isn't going to shut off for 19 hours "! We stopped at the first gas station we came to, filled 'er up, get some snacks and headed north towards Chattanooga. We were on a long drive home, straight through. As you drive, your mind wanders to thought after thought. What a trip! Thinking as I drive, I can't believe we survived. I call my wife, Harriett, every night so I know what's happening back home. It's not easy being away from home for so long! I can't wait to see my wife! After being away for a couple of weeks, what work do I have waiting for me in my sign shop? I set up schedules with customers before I go on a trip, so they know what I am doing. I even keep in touch with them from the Race Track. Still, when I get back to the shop, there is no rest time. I have to start work the first day I'm back! I am going to be swamped!

Little did I know that the grass job we did at Talladega for Britten Banners would be the last "big" grass painting we would do there. The next time we go back to Talladega, I would start a whole new type of painting. We would be known as "the Highwallers". This will be covered in a future series of "Tales".

On the way home we switched off driving at every fillup. The trip went smoothly and we finally made it back home. It was a little over three weeks before Bobby touched any form of alcohol. I had no urge for the "vile brew" myself. That moonshine was that brutal!

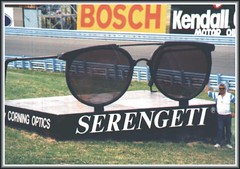

I'm now in my shop working on business signs, lettering some trucks and going about business. I am busy! Mixed in this mess I have at the shop is a call I got from Watkins Glen International. They want to see me about some signs. I get a few minutes and run up to the track. Tim Coleman (now General Manager), tells me of some new sign work. We look over some basic signs, 4'x8's, a couple of 12' x 36' billboards, then he pulls out a drawing and smiling, shoves it across his desk in front of me. I look at it and it is a photo of a pair of Serengeti Sunglasses. What's this? "Do they want this painted on a billboard?" He smiles and says, "No, they want

to know if you can make a pair of these 16 feet wide". I hold the paper up in front of me and say, "are you s****ing me"? "Nope", he says. "They want them mounted on a platform inside of Turn 2 so the camera up in the "Esses" will catch them", he says. "Holy s***", I say again. "Can you do it? They are sending the factory drawings as they want them to be exactly like the real ones" Tim says, looking at me with a "wonder if you can" look. I say, "I will have to think about how to do the lenses". That's the only thing that I see trouble with right now. Each lens will have to be about 6' x 6' ! I left the track with my mind working at a furious pace to figure how I'm going to approach this unique "sign". I really want to do this job! Back at the shop, everything stops. I have to think. This project is going to be FUN, maybe. I will need help. Who can I get to help? I will need someone with warped "vision", an eye for getting something to look like what is on the paper and a mind that could go anywhere. I recently met just the guy! Bob Timmerman. Bob owns a sign shop (Sunshine Signs) in Dryden, NY. He is about 30 miles from my shop. I call him and ask if he would be interested in helping me on the Serengeti project. He's quiet for a few seconds and then says, "Sure, why not". You see, his mind can go anywhere, but getting it to come back is the problem. He often says about his mind, "You don't wanna go in there!" He says, "Yeah, let's do it!" He suggests we do the job at his shop because of the large open area he has. Bob's shop is on the second floor of a huge building. It has a lot of open floor space. Perfect! It's a deal. We are in the "sunglass" business.

We get the "blueprints" from Serengeti and we start to plan. We search and search (before the internet) and finally find a company in Syracuse, NY to cut our lenses. Once cut, we have them coated to match the tint on the real glasses. Now, we have this huge pair of lenses sitting in the shop. The frames are the real challenge. A combination of plywood, 2x4s, 1" foam insulation board, glue and paint and we are ready to start fabrication of a huge pair of sunglasses.

First, we take the blueprints from Serengeti and scale the drawing dimensions upward! We cut the frame shape out of 1/4" plywood. The frames around the lenses are actually curved. To accomplish this, we built a "jig" on the floor and bent the frames (plywood) over it and screwed it to the floor. Then we cut a second frame from 1/4" plywood and laminated it over the first piece. When the glue dried, the frame was taken off the floor and it retained its curved shape. The second frame we cut was a 1/2" smaller on the inside so the lenses would fit in. The bows were formed from 2x4s and a plywood shape was attached for the ear piece. Now we needed shape. We glued foam board to the frames and ear piece. With a lot of grinding and sanding, we finally got the foam into the shape we wanted. A nice paint job and they were ready for delivery. One good thing that came from this job is that Bob and I became best of friend's. He appears in later "tales".

At the track, they caused quite a stir! Drivers often commented on them after they came back in after a run. "I came around Turn 2 and there were these huge, f****** sunglasses"! was often heard. Serengeti was happy! They were a pain to put up. You see, they could not be left out. We were afraid of wind and vandalism, so before each race, they had to be put on a flatbed truck, hauled out to the platform, put together and set up, then right after the race taken apart and hauled back to the storage building. Once, after a race we caught a fan coming across the track with a cordless drill. He was headed for the glasses! As drunk as he was, I don't know what he was thinking. He never could have carried them off alone.

Jobs like this make me proud when we are done and it turns out as it should. I couldn't think of working in a factory or office. This job is for me! I often sit and wonder if something "new" is ever going to come about again. So far these "new" jobs always have a way of showing up when you least expect it.

A year goes by and Talladega calls. This time the message is completely different. Seems they contracted the grass to a new company in Atlanta. A new marketing twist at Talladega has produced a new theme, "Big and Bold". They want this all over the place. There will be a large number of signs ranging from 4'x8' signs to signs that are in the 200 sq.ft. range. We decide to use Alumalite for the panels. This is a great material. It is made of two sheets of aluminum with a 1/4" plastic core. Very rigid and light. I decide to do the signs in my shop over the winter and then put them in a truck and take them down when we go to the Speedway. They figure we will be there two weeks. Also they say, they want some lettering on the retaining walls. I want to make "Pounce Patterns", but they do not have artwork yet. To solve this, I decide to box up my 30" plotter, computer, scanner and printer and take them with me. There is an office in the sign shop at the Maintenance building that I can set up my equipment. Signs finished, we are ready to once more go back to Talledega.

I will need help. A few years ago, Steve Hughey came to my shop, when it was In Ithaca, NY, to see my new Gerber Vinyl cutter. I was one of the first in the area to have one and he wanted to see it work. He owned a sign shop in Corning, NY and we became very good friends. One day, on the golf course, Steve brought along this sad excuse for a human by the name of Larry Orr. Would you believe he owns a sign shop in Lindley, NY! Needless to say, we became best of friends. As a matter of fact, his wife Sally, hosts this "blog" site. Did you see the word "golf" a few lines back? We are all addicted to the game. To this day, we (Bob, Steve, Larry and me) meet once a week at a different course and proceed to tear each other up with verbal abuse and slurs. This golf thing carried over to our trips as you will see later.

At this time, Steve had a helper, who now has his own sign shop, named Brad Daudlin. He lives in Beaver Damns, NY. Brad had an older, Brown Ford Pick Up. Sound familiar (Britten Banner truck). He wanted so much to go on this trip, so we said, "you haul the signs down and you can go". We loaded the truck with the signs and away he went, front wheels off the ground. He left a couple of days before we did as he wanted to stop along as he had a hell of a load in the truck and wanted to take his time. We decided to take my wife's Ford Explorer. All of my computer stuff and our sign kits fit in it. Larry and Steve would ride with me. This mission would be different. Much different. So much so, it would set the stage for a different kind of painting for years to come.

We arrive at the track about 2 in the afternoon and greet Mike and the gang. It is getting like we never left. We park at the Sign Shop, located in the Maintenance building and start to unload the "stuff". Brad is already there unloading the many signs so we help him first. There are so many signs! We stack them along the wall of the shop. Inside we set up all the computer stuff. We are here! We are ready for this new challenge, whatever it is. Officially we start work tomorrow, but getting this "set up" stuff done early, really gives us only a day.

Monday we are at the track by 7a.m. We go into the "coffee" room where Mike and a few other guys are already planning the day and of course the regular round of bulls***. Today Mike wants to start putting up the "Big and Bold" signs. Then he says, "let's go for a ride, I want to show you where we want new logos." I get in the truck and we head for the retaining walls on the "high banks" off the race track.

Lap 14: We become "Highwallers"

8 Comments:

What were the lenses made of? Plexi glass?

The lenses were Lexan, an unbreakable plastic, coated with a tinted film.

were those lenses formed, or were they flat. would smoke plexi have worked?

The lenses are flat Lexan, but due to the curve of the frames, they are bowed. The smoked plex would work, but the color of film used, matches the original lense color. Almost a perfect match.

Who ended up taking the glasses home?

Since they had to be taken apart and put in storage after every race, after the year of Serenget's sponosrship had ended, the galsses were in rough shape. I think they were destroyed. But, I will check with the Race Track and find out for sure.

How did you achieve bowing the lenses? Vacuum forming? Who made the mold?

The frames were laminated with a slit bow in them. It is in one direction, so the lenses lust bend around.

Post a Comment

<< Home